Power Generation

Fuel sources for power include coal, Liquefied Natural Gas (LNG), Biomass, oil, gas, solar, wind, hydro, nuclear or even fruit pits containing high BTU value. Some of these types of systems can be constructed in out of the way locations, as well as close to the source placement. However, there are many factors to consider in the decision process regarding the best source for your business.

LNG (Liquid Natural Gas)

LNG is a viable fuel source for large scale power generation. It currently makes up approximately 23% of global power generation. In the US, 42% of all power generated is LNG. The power generated by this fuel requires distribution using transmission lines to the end user. In addition, the delivery of LNG is typically achieved using large-scale delivery means, such as ship-to-shore storage vessels or surface/underground pipeline delivery to the point of generation. Ship terminal or pipeline delivery to the generation source has additional cost of power but is still one of the most cost-effective sources of generated power. The CO2 discharge from burning this fuel is less than half that of coal. LNG will continue to be an expanding and cost-effective source of power generation going forward. The permitting and construction for this type of power plant is 3 to 5 years.

Due to the Russia / Ukraine war, supply line from Russia routing through Ukraine servicing parts of Europe of will be shut off as of December 31, 2024. LNG producing nations including the USA will need to provide LNG to make up for these losses.

Coal Fired Generation

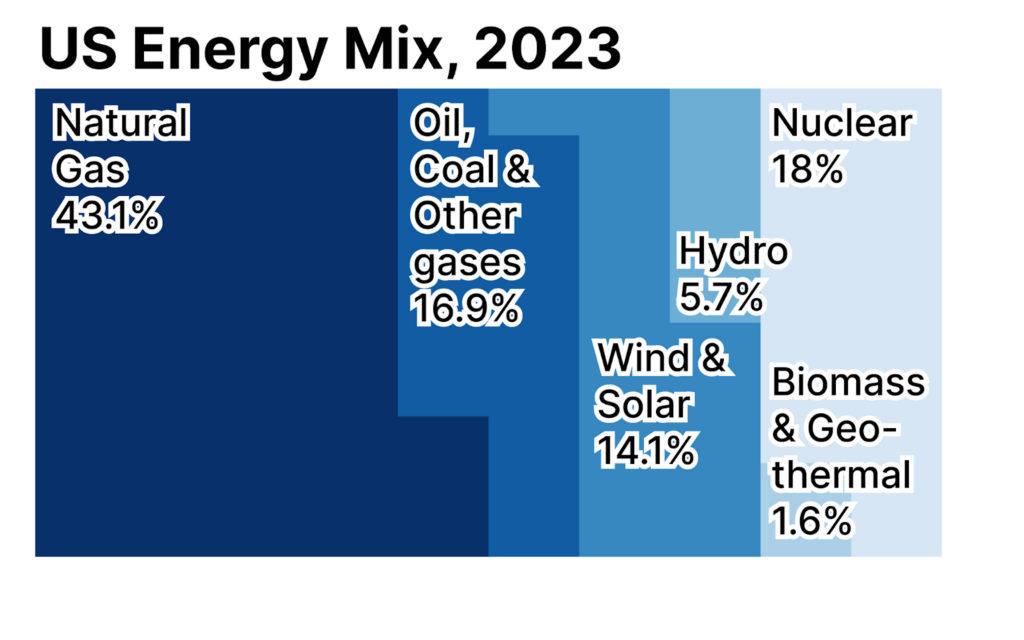

Coal and other carbon-based materials, such as oil, have been dependable and cost-effective means of generating power for generations. Combined, they provide 16% to 18% of all generated power in the US today. Transporting this material from their source to the point of generation is effective, affordable, and reliable. The US and countries round the world have long benefited from their use and can be credited with furthering the industrial revolution, benefiting humankind as it transformed humanity for the past 140 + years. However, burning these fuels currently releases the highest amount of CO2 gas into our atmosphere of all fuel used for large scale generation. The US and other Western governments are looking to transition from using coal to other forms of power generation. Unfortunately, many countries around the world still rely on these fuels and will continue to do so for some time. In the U.S., the average coal fired power plant takes approximately 4 to 7 years from EPA permit, construction and licensing for a new facility. In comparison, China is in an 8-year growth mode of new coal generating plants, representing 95% of the world’s expansion ×××.

Wind/Solar

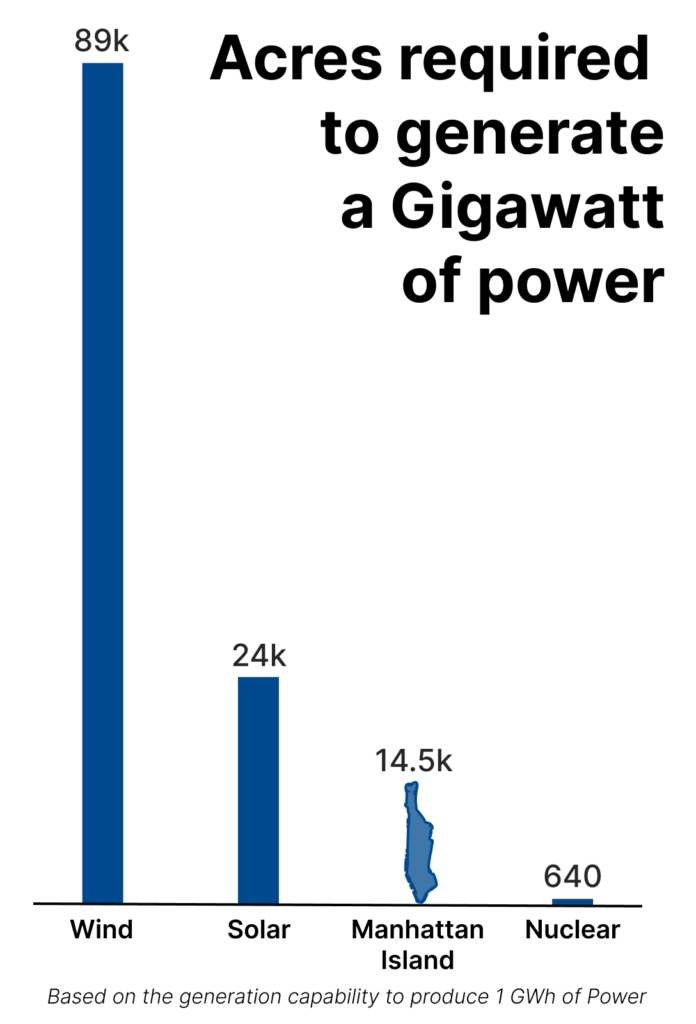

Wind and solar generation farms require hundreds of acres to create large scale power and are considered low power density systems requiring a big footprint of operation. They must also be placed in locations which maximize the availability of wind or sun. In most cases these are remote locations, meaning the power must then be transmitted from the source to the end user’s location. Wind/Solar represents 15.6% of total power output in the US today.

Wind and Solar power is not considered a suitable source of power for customers needing high reliability power sources. These systems use backup sources of generation in the event wind/solar output is not available. Both systems can store power using molten salt heat exchangers or battery storage systems, to assist in providing power during long periods without wind or sun. However, these backup systems only provide coverage for a limited time. Backup sources are in turn connected to high voltage primary generation power transmission line systems allowing Independent System Operator (ISO) to scale down back-up generation when wind/solar is at optimal output.

Drawbacks to Turbine Wind Systems ‡:

- Wind is intermittent.

- Wind speeds above 55 MPH cause the turbine to stop operating.

- Power output can be rated by the wind speed, lower wind speed means the turbine is not producing its maximum output.

- Turbines kill birds when operating.

- Wind turbines create a low audible noise disturbing both wildlife and humans.

- The “North American power grid warns that the combination of rapid retirement of coal-fired electricity generation and the increasing reliance on wind and solar are risking large swaths of the United States with blackouts during heat waves and cold snaps ˩ ˩ ˩.”

The life expectancy of wind farms is similar to solar facilities lasting 20 to 30 years. Disposal of end-of-life wind mill generators is still under discussion by the industry. The blades require specific processing due to the chemical coating and construction of the blade. Re-fitting, or “repowering” as the industry refers to it, is possible using the latest technology systems for older wind farms. Repowering may increase the power output of the older systems, depending on the size and technology of the new units.

The average solar power plant currently lasts 25 to 30 years, as overtime panels begin to significantly fall short of their original power output curve. Panels can be replaced and restarted once re-fitting efforts are completed. Disposal methods of used panels have yet to be completely addressed by industry and the regulatory agencies††.

As a comparison, according to the NEI, to generate one (1) gigawatt of nuclear power requires approximately 640 acres to operate. The equivalent power output from Wind / Solar require 89,000 and 24,000 acres respectively ±±. See chart below.

Wind and solar will remain a viable source of power generation in the US for a portion of the country’s needs for the foreseeable future. However, the Inflation Reduction Act (IRA) of 2022 requires changes that will affect the market, as there is a growing resistance at local levels because of federal tax treatment of investment and production tax credits as the principal drivers behind the deployment of wind and solar energy. These provisions make solar and wind energy the most expensive energy-related provisions in the federal tax code. The new (2025) administration is looking to reduce or eliminate these code provisions for wind and solar projects.

Thermal Solar or CSP

This power source is a variation on solar panels, but the system uses mirror-like surfaces to reflect the sun’s rays to a receiver tower (Concentrated Solar-Thermal Power). Unfortunately, a facility called Crescent Dune Solar Energy Project located in the Nevada desert west of Las Vegas and funded in part by the Obama administration DOE has failed to turn a profit since its commissioning in 2015. The system never performed up to design expectations and had multiple long-term outages for repairs. NV Energy cancelled its contract with Crescent Dune in 2019. The US government is currently in litigation over tax dollar fundings ×.

Hydro Generation

Hydro power generation in the US represents 5.5% of total power production per year. Most of this power is concentrated in Washington and California. On the east coast, New York and Alabama represent the largest source of hydro generation. This type of power is completely renewable and does not add pollutants into the atmosphere. Expansion of hydro plant power in the U.S. is not likely due to its environmental impact from damming rivers and its surrounding environment.

Alternate Fuels

Geothermal, Biomass and even fruit pits high in BTU value material are viable sources for power generation; and are also considered renewable. Geothermal plants are highly economical, but these resources are not plentiful. Other source materials burn at high temperatures and provide a reliable means to generate steam-driven co-generation power. This sector produces 2.4% of the US power generation per year. It remains the smallest generation component in the power sector. According to a study by ORNL in 2024, indicates the biomass industry may need additional market maturity to be sustainable.

Nuclear Power Generation

The US currently employs 94 nuclear generators located throughout 28 states and generates 97 GW representing 18.2% of U.S. power generation. These units are considered large scale facilities, each unit producing approximately 1 GW (gigawatt) of power each.

Large Scale Reactors

Vogtle Unit 4 at the Alvin W. Vogtle Electric Generating Plant in Georgia is the newest power plant and produces 1,144 (MW). Vogtle units 3 & 4 are the latest reactors built in the past 30 years and were activated in 2023 and 2024. Reactors are licensed by the Nuclear Regulatory Commission (NRC) to operate for 40 years with a possible 20-year extended license agreement. This type of nuclear power generation represents an enormous undertaking of both time and money to create. Vogtle unit 4 located in Georga, began development 11 years ago with a $30 BN cost of construction, more than double its original estimated price tag. These reactors make it the largest producer of nuclear power in the US generating 5 GW of power 24/7 when all 4 units are in operation. The power generated by these units is distributed all over the southeastern region of the U.S. These units represent a massive commercial commitment by utility operators, states, federal and local governments, and require the NRC to provide management and oversite of their operation. Developing power generation of this scale takes years to negotiate and charter before a single building is constructed. The hidden costs of distributing power (transmission lines) have not been calculated into the above project costs. The commitment to these large-scale projects will continue as corporate enterprise users have immediate and growing needs to satisfy their power requirements. These large applications and modern SMR units are beginning to overcome the stigma of the 1979 incident at Three Mile Island, the Chernobyl reactor in 1986, and at Japan’s Fukushima Daiichi accident in 2011.

SMR Technology

In the early 1940s, the USA proposed the first High Temperature Gas Reactor (HTGR) unit concept. The first Small Modular Reactor (SMR) Fusion technology was developed by the Fermi Atomic Power Plant in Michigan in 1963. In the early 1960’s the UK developed a demonstration model and by the mid-1970’s several countries developed experimental HTGR ranging from 10 to 46 MW of power output per year. China and Japan’s units remain in operation today. The US Navy and Army developed and operated SMR technology starting in the 1950s. The Army operated 17 units until they were taken out of operation in 1976. The US Navy found the technology far more useful and with a limitless budget obtained successful operational units. In 1955 Naval Submarines began using SMR devices, and large aircraft carriers followed suit in 1960. Today’s Aircraft Carriers variant produces ~500+MW per unit with two units operating in each vessel.

As of 2024, there are approximately 17+ corporations developing SMR products with some seven variations of reactor types being built, the others are in the conceptual design phase. The designs incorporate water-cooled, gas-cooled; fast spectrum; molten salt, and micro reactors technology. Of these groups, only two SMR variations have achieved operating or concept licensing from the NRC, NuScale and Kairos Power. As of December 13, 2024, the Westinghouse SMR has also received approval from the NRC.

SMR technology versus large scale nuclear reactors are different in their operating scale and management oversight requirements. SMR units produce between 1.5 MW to 300+MW per unit. There are three categories of SMR based on their range of power output: vSMR (v= Very) under 15 MW, SMR between 16 to 300 MW all other units are custom usage. The operating fuel is completely different than large scale generation. Many of these newly designed units use a product called TRISO fuel (TRi-structure ISOtropic), a microsphere encapsulated by successive layers carbon and silicon carbide shell to prevent release of radioactive fission products; also called HALUE (High Assay Low Enriched Uranium) ɬ ɬ. The atomic material is refined to 5% to 20%, compared to nuclear weapons grade refined to 90+%. In this configuration, TRISO fuel is highly stable; if cooling to the reactor vessel is lost the reaction will not cause the unit to melt down. There are some SMR designs using helium to circulate this hot gas material; if lost due to mechanical failure or rupture, the system simply stops the reaction. This is only one of many systems the industry is promoting with a high reliability of operational safety. Many SMR designs are incorporating operational functions that eliminate the need for full-time system operators. This is a major step forward for industry.

Uranium Fuel Availability

The world’s largest deposits of uranium ore are Australia, Kazakhstan, Canada, Russia, and Namibia. Canada’s Saskatchewan’s Athabasca Basin represents the third largest deposit in the world with the highest-grade atomic material concentration per Metric ton of 17.03%. Although Australia has the largest deposits in the world, the country has stopped much of its mining efforts due to community pushback. Kazakhstan’s materials are not now accessible to the US due to the ongoing war in Ukraine. Uranium form Russia is also not unavailable.

Canadian uranium is a prime resource for nuclear power generation expansion in the US. It is a high grade of ore with an abundance of material and proximity to the US Oak Ridge KY and Idaho Nuclear processing facility ˩. In December 2024, the US government announced its intent to award contracts to process low-enriched uranium, or LEU in the United States, as opposed to relying on foreign sources.

Fusion Technology

The study of nuclear material dates to 1789 with the discovery of uranium, followed by major scientific developmental discoveries in 1895. The atomic age for humanity really begins to take shape in the early 1920s. By the 1930s scientists discovered nuclear fusion was possible and was able to “harness the energy of the sun.” In the 1950s governments around the world began funding and studying various theories to harness fusion energy. Russian scientist promoted the use of a Tokamak (“toroidal chamber with magnetic coils”) process to create a contained plasma flow of fusion using strong magnetic fields. Other theories such as the stellarator were considered, but over time it was determined the Tokamak process was more effective. International Thermonuclear Experimental Reactor (ITER), (Latin for “the way”) a term used in the industry to help define the need for fusion and its development, and the arduous efforts to unlock the tremendous energy of the universe. The stellarator approach has not been abandoned, and development continues at Princeton Plasma Physics Laboratory, in Germany at the Max Planck Institute for Plasma Physics and other startup groups in Europe.

Many advancements have been made since the 1950s with billions spent by Europe, USA, China, Japan, and others. The US invested in the NIF (National Ignition Facility) technology located in Livermore CA. NIF employs the use of 192 sophisticated lasers, all focused on a single point, the size of a pencil eraser. Through a process of amplification and laser focusing the reaction is initiated. The power needed to start a fusion process is 2 million joules (MJ): the heat required to raise the temperature of water from 32 degrees Fahrenheit to 33.8 X 2,000,000. This reaction generates ~180 million degrees Fahrenheit.

As an example, NIF has achieved a scientific gain of ~2,4 MJ where fusion output of ~5,4 MJ was produced by an incident laser energy of ~2,2. This is the first time for all fusion approaches. The length of time the reaction is allowed to continue is limited to mere moments for safety reasons. The technological challenges required to contain and control these processes are immense. Industry must find materials or modify the process to contain the temperature of the sun here on earth. The future is bright indeed, but developing solutions to these challenges may take decades.

Without Tritium, fusion ignition cannot be sustained, it acts as a fuel for the continuous reaction. Although it is an element it is not abundant in nature. It must be produced by taking Lithium-6, an isotope, and “breeding” it by processing them in a reactor. This creates 3H (Hydrogen 3 atom) or tritium. Processing and breeding these substances has been done since the early stages of the atomic age at substantial cost and using environmental caustic methods. The industry is working to simplify the process enabling it to store tritium for future use. A lot of material will be needed.

Author:

Mark Cuzner, CEO

CICS, LLC

Foot Notes:

- * https://www.dailyrepublic.com/news/fairfield/fairfield-brewery-gets-mammoth-wind-turbine-to-power-plant/article_168d3c47-2ce4-5cce-9597-f942f3b6d2bf.html

- ** https://www.ans.org/news/article-6555/us-unveils-road-map-to-triple-nuclear-capacity-by-2050/

- † https://www.power-grid.com/td/the-u-s-has-a-critical-shortage-of-power-transformers-can-it-bounce-back/

- †† https://www.energysage.com/about-clean-energy/wind/pros-cons-wind-energy/

- ‡ https://www.solarreviews.com/blog/wind-energy-pros-and-cons

- ɬ https://www.ans.org/news/article-6573/new-welding-school-opens-for-high-schoolers/

- ɬɬ https://www.energy.gov/ne/articles/triso-particles-most-robust-nuclear-fuel-earth

- ˩ https://investingnews.com/top-uranium-reserves-by-country/

- ˩ ˩ https://www.fortunebusinessinsights.com/transmission-line-market-106347

- ˩ ˩ ˩ https://justthenews.com/politics-policy/energy/grid-watchdog-warns-future-blackouts-and-need-natural-gas-power-support

- × https://www.breitbart.com/politics/2024/11/25/exclusive-crescent-dunes-biden-doj-moved-election-night-cover-up-alleged-solar-energy-scandal/

- ×× https://www.whitehouse.gov/wp-content/uploads/2024/11/US-Nuclear-Energy-Deployment-Framework.pdf

- ××× https://www.carbonbrief.org/china-responsible-for-95-of-new-coal-power-construction-in-2023-report-says

- ¥ https://justthenews.com/politics-policy/energy/rural-communities-fought-wind-and-solar-developments-2024-some-states-may

- 0 https://robertbryce.substack.com/p/heres-the-real-hockey-stick

- 00 https://www.eia.gov/tools/faqs/faq.php?id=427&t=3

- ±± https://www.nei.org/news/2015/land-needs-for-wind-solar-dwarf-nuclear-plants